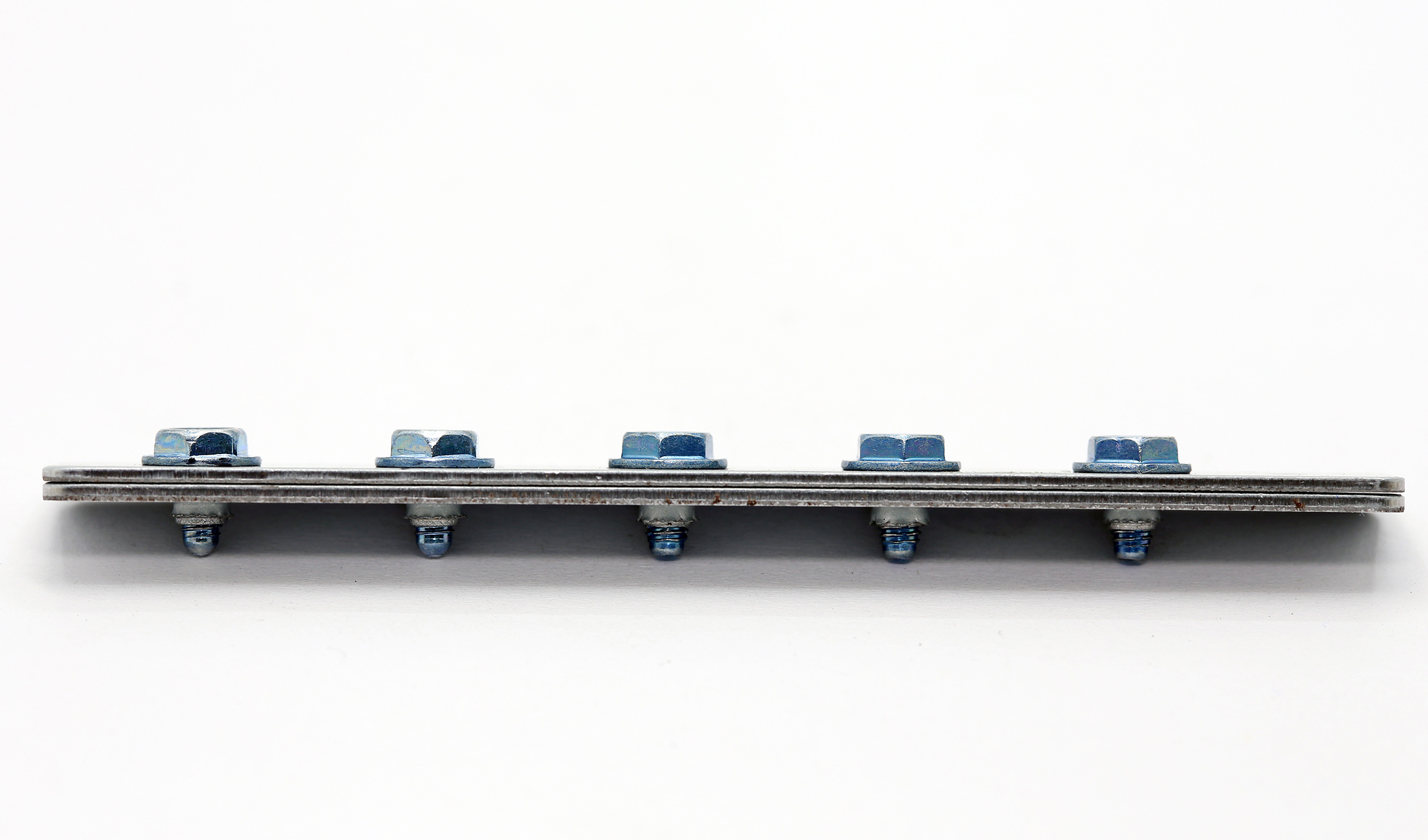

For thick metal components, pre-tapped internal threads or matching nuts are typically used. Corresponding screws are graded machine thread screws, with precision levels and effective thread engagement length determining performance. Common mechanical grades include 4.8, 6.8, 8.8, 10.9, and 12.9, selected based on application requirements.

To prevent loosening, solutions include combining elastic washers, applying threadlocker, or installing anti-loosening nuts—all measures that mitigate or eliminate screw detachment.

For low-strength metals (e.g., aluminum, magnesium, cast iron), stainless steel threaded inserts can be added to pre-tapped holes, enhancing connection strength and wear resistance.

Due to the thin nature of sheet metal, connection methods such as welding, riveting, or snap-fit can be directly applied for secure and efficient assembly, though disassembly is not repeatable. For detachable applications, welded screws or nuts—widely used in cabinets and chassis—are recommended.

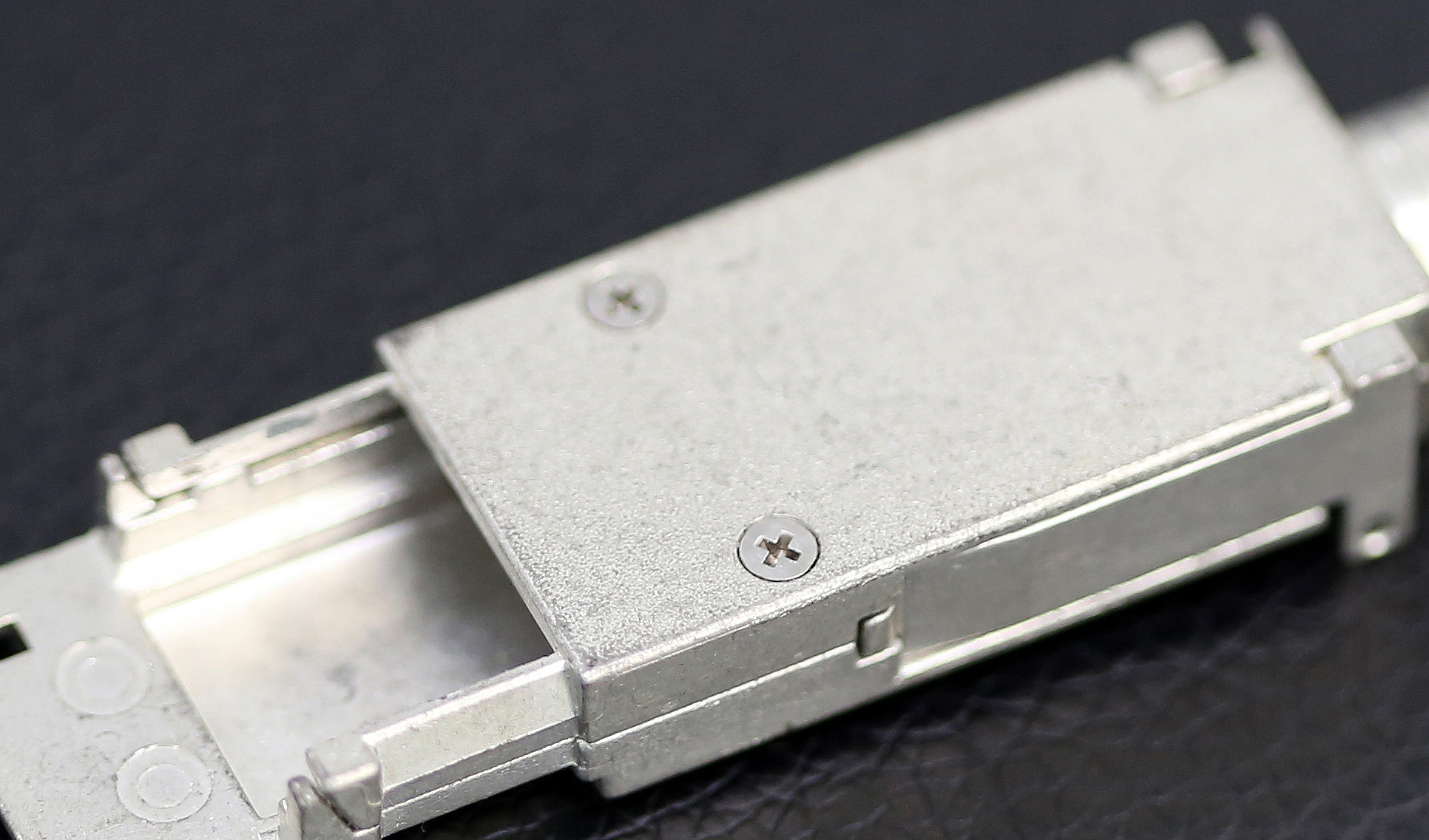

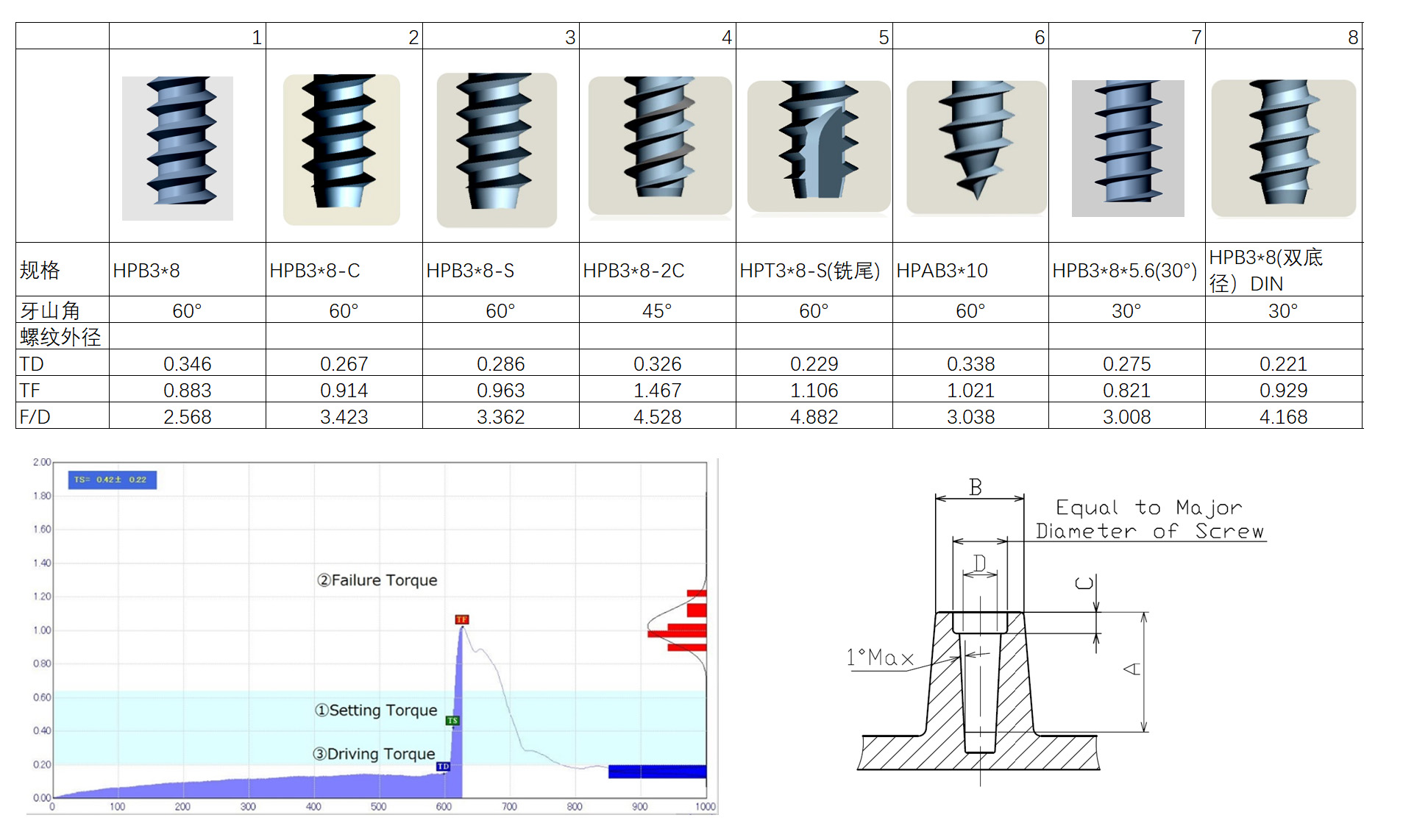

Creating flanged holes in sheet metal and using self-tapping screws (e.g., Type C/S/B triangular screws) is an optimal solution. These screws excel in self-tapping, self-locking, and self-tightening functions, making them increasingly popular in printers, servers, and household appliances. To reduce assembly friction and torque, screws may undergo wax-sealed treatment.

Screws are widely used in plastic component connections, particularly in electronics, automotive parts, toys, and industrial equipment. Due to plastic material characteristics (e.g., low strength, deformation susceptibility, high thermal expansion), selecting appropriate thread types is critical. Self-tapping screws are the primary choice. For softer plastics like ABS, PP, or PE, self-tapping screws with wide thread pitch and small flank angles (e.g., 45°, 30°) are recommended.

For high-load or frequent disassembly scenarios, embedded threaded inserts can be pre-installed using methods such as press-fit, thermal fusion, ultrasonic welding, or in-mold forming.

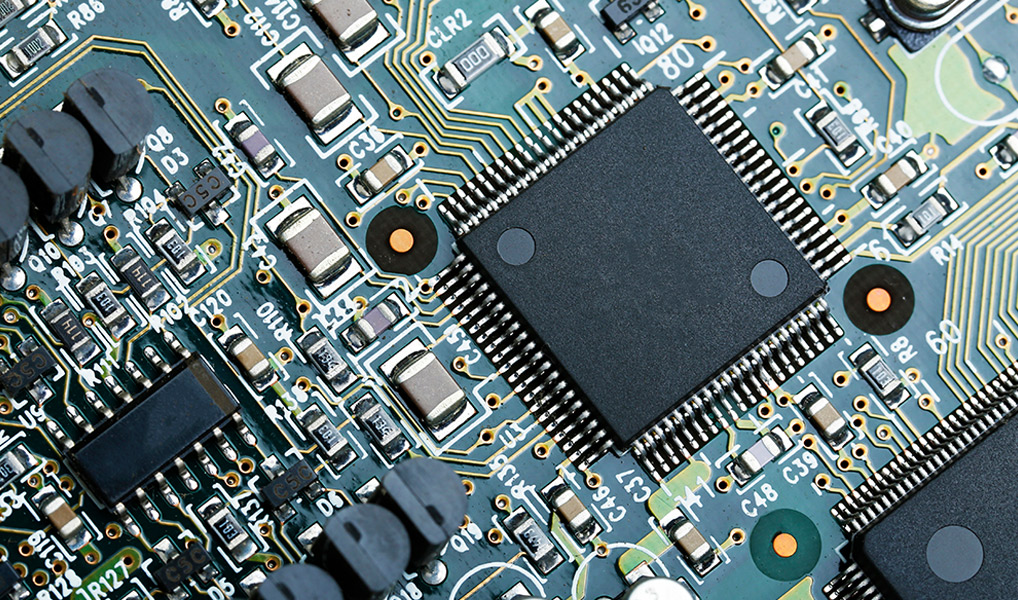

The electronics sector—including 3C products (computers, mobile devices, wearables, and consumer electronics)—operates in a fiercely competitive environment. Component supply faces three key challenges:

1.Rapid iteration: Understocking risks unmet demand, while overstocking leads to excess inventory due to abrupt product phase-outs.

2.Volatile order volume: Orders surge unpredictably, straining production capacity, only to recede just as sharply.

3.Cost sensitivity: Relentless pressure to reduce pricing.

Adopting digitalization and lean principles optimizes inventory and flexible production. Collaborating with partners to build a robust supply chain is imperative, as future competitiveness depends on entire supply ecosystems, not individual entities.

The automotive industry prioritizes reliability. While development cycles are shortening as vehicles evolve into electronic-centric products, safety requirements remain the same, if not more stringent.

Screws for different application scenarios are controlled at different levels. Screws for critical parts of the engine, chassis, suspension, braking system, etc. must have extremely high tensile, shear and fatigue strengths, and any negligence may bring about serious consequences, and therefore are the most stringent control level. In contrast, the risk of door locks, seats, lights, dashboards will be a little smaller, and the risk of interior parts is even smaller. However, whether it is a critical or non-functional part, whether it is supplied to the main car factory or a secondary or tertiary supplier, the in-vehicle product should have full traceability from raw material to assembly.

Spare parts in the medical industry are concerned about compliance in addition to reliability. Based on risk-based thinking, he doesn't want you to make more proposals like electronics or automotive manufacturers, he wants you to be stable and not change all the time, so he cares a lot about your change management. He might also have biocompatibility and sterility requirements if there are parts that come in contact with the human body.

The ISO 13485 system highlights the importance of regulations, ensures the quality and safety responsibility of medical device organizations, and applies to all stages of the full life cycle chain.

In the robotics industry, the pursuit of lightweight drive systems and structural components, some joint module connection and fastening is particularly important, the requirements for screws will have some obvious characteristics: high strength, lightweight, anti-loosening, high salt spray, for the appearance of the screws are also required to be beautiful and anti-dismantling. At this point, carbon fiber screws is a good choice, M3 and M3 screws we can achieve the production of carbon fiber materials.